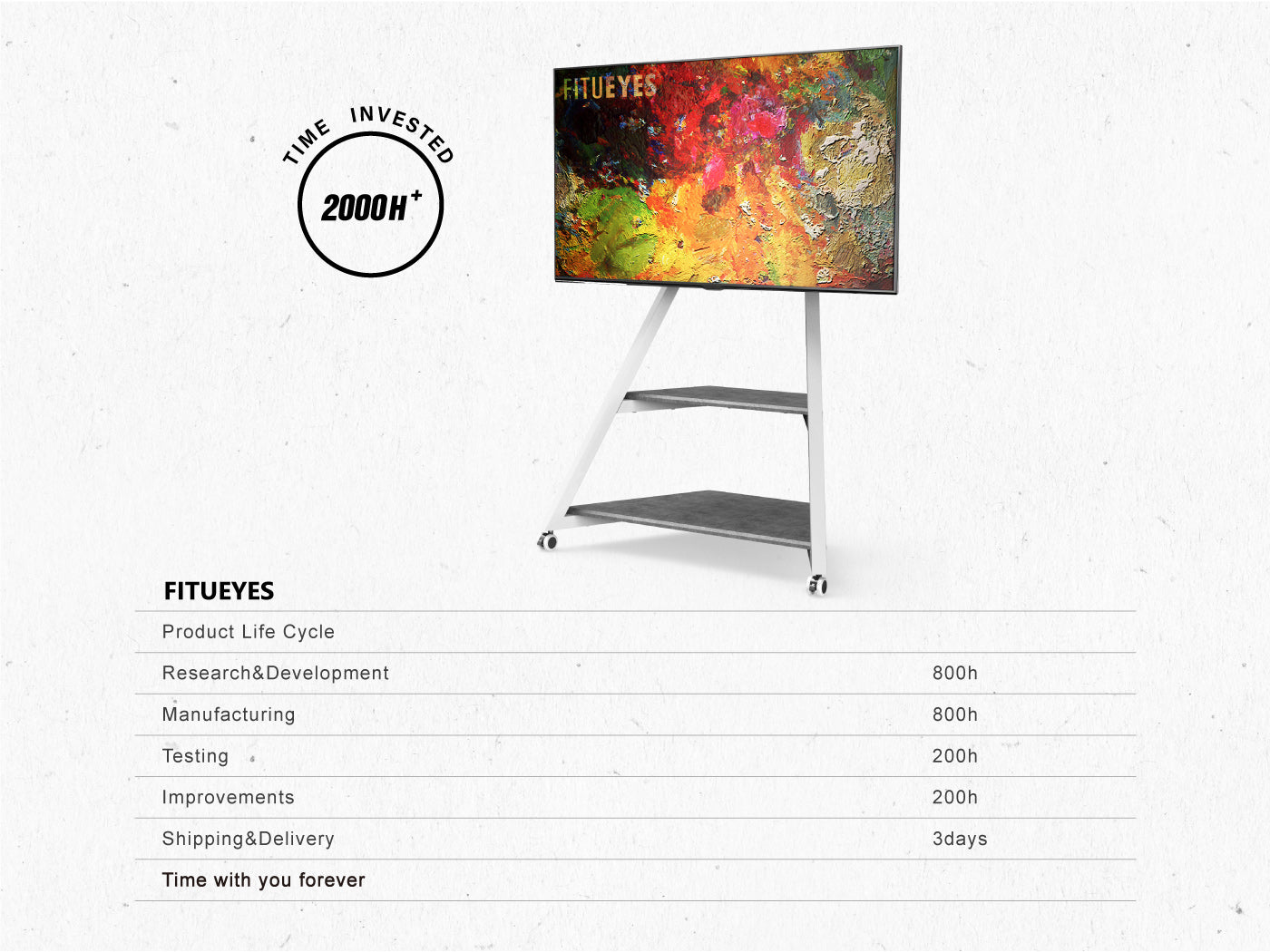

Have you ever heard of Jaeger-LeCoultre’s 1000 hours test? As one of the top watch brands, Jaeger-LeCoultre has always been known for its exquisite design and outstanding quality. Jaeger-LeCoultre has established a rigorous test standard known as the "1000-hour test" to assess and record data and details of newly produced watches. This stringent test standard has earned Jaeger-LeCoultre a stellar reputation, setting it apart from its competitors. In today's world, more and more consumers value the time a company invests in perfecting its products, making it an essential benchmark for assessing product quality.

Committed to Quality and Customer Experience

As a global professional designer TV stand brand, FITUEYES is unwavering in its commitment to ensuring product quality and enhancing the customer experience. When we embarked on the development of the Fitueyes Floor TV Stand Eiffel Series, we initiated a comprehensive process. It began with our marketing department conducting thorough market research to understand customer demands.

Following this, the FITUEYES designers and engineers came together for extensive discussions on industrial design and structural design. These deliberations, often accompanied by moments of inspiration and ingenious ideas, sometimes involved disputes but were essential to shaping the product. This process alone consumed 54 working days. Once the design draft was finalized, we dedicated 45 working days to creating a sample and subjecting it to a battery of tests, including load capacity assessments, functional tests, and assembly evaluations. These tests provided valuable guidance for product improvements. The entire research and development (R&D) process typically exceeds 800 hours.

Meticulous Manufacturing: Ensuring Quality

The manufacturing phase was equally critical. It encompassed mold design and trial production. At FITUEYES, we are adept at identifying the best factories that offer sophisticated production equipment, excellent production technology, and a safe working environment. Prior to commencing mass production, mold samples undergo rigorous load capacity, functional, and assembly tests. Any issues identified prompt immediate modifications to the mold samples. This process, too, demands significant time and effort, totaling more than 1200 hours. However, we believe the investment is worthwhile, as it contributes significantly to product quality assurance.

Effortless Access for Customers

Once everything is in place, we make the FITUEYES Floor TV Stand Eiffel Series available on our website. To enhance customer convenience, we have streamlined the purchase process, allowing customers to complete their orders with just a few simple clicks. Shipping and delivery typically require only 3 working days. Despite the tight timelines and demanding tasks, FITUEYES is dedicated to ensuring safe transport and delivering products to our customers in impeccable condition.

In Conclusion: The Dedication Behind Each Product

In conclusion, behind every product lies the unwavering dedication of the FITUEYES team. We hope that our products will accompany you for as long as possible, enriching your life and enhancing your living spaces. Your satisfaction and enjoyment are our ultimate goals.